Green Cement Transformation Project

The Hallett green cement transformation project is the most significant carbon reduction innovation project ever contemplated in the Australian cement and concrete industry. Hallett Group will construct a sovereign manufacturing capability to process and distribute 3 streams of Australian generated industrial waste by-products into low carbon green cement products utilising established renewable energy sources. With a job creating investment of $125 million split across the regional city of Port Augusta along with new infrastructure in Port of Adelaide the project will reduce Australian CO2 emissions of 300,000 tonnes per annum immediately, growing to approximately 1 million tonnes per annum in years to come. This amounts to approximately 1% of the entire Australian 2030 CO2 reduction target.

ABOUT HALLETT GROUP

Hallett is a 100% proudly Australian owned and operated business which together with its preceding entities has been a market leader and large employer in South Australia for the past 40 years. Hallett supplies a range of products and services for the Mining, Building and Construction sectors. Its industry leading offerings include cement, mining materials, concrete, quarry products, technical and laboratory services, logistics, timber, trusses, structural steel, building products and much more. With a mission to be dominant in its chosen markets Hallett continues to invest extensively in its people and capability to meet its goals.

ABOUT THE GREEN CEMENT TRANSFORMATION PROJECT

Cement is responsible for 8% of global carbon emissions or 3 billion tonnes of Carbon Dioxide (CO2) per annum*. Cement is the major constituent material of concrete which is the highest volume construction material consumed globally. Cement is therefore a key component in supporting the economic activity generated by the construction industry. Cement is also used extensively in mining activities such as stope backfilling and underground tunnel support. Australia currently consumes around 12 million tons per annum of cement with around half of this imported in the form of finished (powdered) cement or cement clinker. At a current carbon intensity of 0.87 tons of CO2 produced per ton of cement this represents a significant carbon reduction opportunity.

Hallett will use existing and proven technology to manufacture supplementary cementitious materials (SCMs) that can replace greater than 50% of traditional high CO2 emitting clinker-based cement. The primary manufacturing operation will be based at Port Augusta, South Australia and will extract and utilise historic waste flyash from the previous Port Augusta power station operations. It will also provide the Nyrstar Port Pirie multi-metals smelter with the opportunity to provide valuable materials into the project and reduce onsite environmental footprint.

The project will immediately replace imports of SCMs and will future proof Australia’s access to SCMs and green cement which becomes increasingly important as Australia’s current locally produced sources of SCM quality flyash diminish in coming years in line with the reduction of coal fired power generation. With existing material reserves and ongoing production offtake Hallett can provide the market with 30 million tons of SCMs over the next 20 years and beyond. This surety of sovereign supply will promote greater uptake of SCM cement replacement and green cement with significant scope to drive down the 12 million tons P/A of high CO2 emitting clinker-based cement demand in Australia.

*(Ref. “Beyond Zero Emissions” Zero Carbon Industry Plan – Rethinking Cement; 2017)

THE PROJECT ELEMENTS

Hallett is building an integrated Green Cement business incorporating:

- A granulated slag offtake agreement to consume the existing offtake and reduce current onsite, secured, material of granulated slag produced at Nyrstar Port Pirie

- A flyash offtake agreement to extract and process flyash from the legacy ash storage area at Port Playford. Note that extraction of this resource will be highly controlled with only progressive disturbance of the area tied to the requirement to achieve zero community dust impact.

- A combined SCM processing facility and Green Cement blending and distribution hub at Port Augusta powered by locally produced renewable power (Wind & solar). The facility will process SCM products by grinding them individually or inter-grinding and blending with various activator products sourced through Hallett’s Port Adelaide distribution hub and other sources.

- A Green Cement blending and distribution hub at Port Adelaide combined with import and export capability. The facility will consist of a 52,000-ton cement storage dome, 15,000-ton flexible SCM storage shed and state of the art blending and distribution functionality.

- All the technology, equipment and production processes are off the shelf solutions, with demonstrated performance all over the world. The innovation comes by processing SCMs through a single facility followed by the specialised blending processes to make tailored product solutions for a broad range of applications.

Port Augusta Green Cement Processing Hub

Port Adelaide Green Cement Distribution Hub

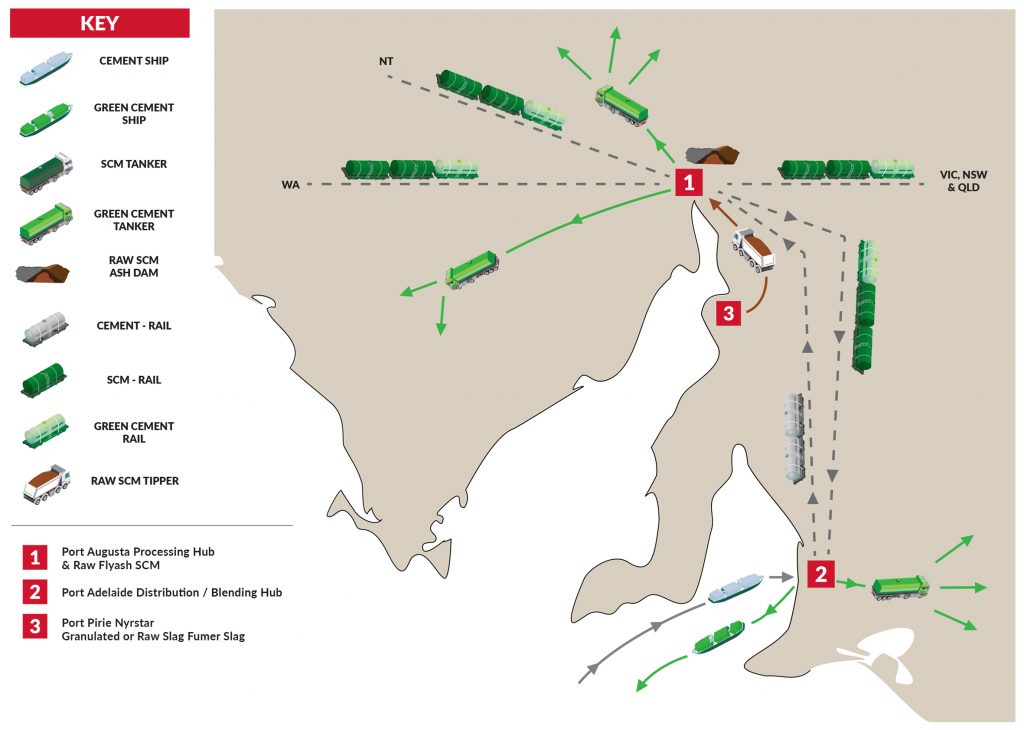

THE MARKET AND LOGISTICS PATHWAYS FOR SA PRODUCED SCMs AND GREEN CEMENT

- Green Cement for use in mining.

- Green Cement for use in construction concrete.

- Ground Granulated Blast Furnace Slag (GGBFS) for use in construction concrete.

- Flyash for use in construction concrete.

- Green Cement for use in geopolymer concrete

- Green Cement for use in other construction and construction product applications

- Green Cement and SCMs for use in road stabilisation

The SCMs and blended green cement products manufactured at Port Augusta will be sold and utilised across Australia with the potential to export green cement products throughout the greater region.

The project in a single picture

PROJECT BENEFITS

- 1.15 million tonnes of cement replaced completely with SCM can reduce CO2 emissions by 1,000,000 tonnes becoming a strong contributor to State and National emissions reductions targets.

- Will deliver long term employment opportunities in the upper Spencer Gulf with the processing facility, granulation plant and associated activities expected to generate >50 full time jobs in operation, hundreds throughout the construction phase and provide extensive work for local service providers and contractors.

- Contribute to the long term sustainability and community license of Nyrstar at Port Pirie and Port Augusta Operations.

- Powerful contributor to emission reduction targets and social license obligations of Mining Customers.

- Significant logistics cost saving opportunity for current incumbent miners and being able to present similar savings to future new mining participants can only assist in enhancing the viability and sustainability of future new mines.

- The opportunity to set up the Port Augusta processing hub to operate on 100% renewable power straight from the Port Augusta renewable energy park. The grinding operation will have the flexibility to manage demand loading during peak demand to enhance overall grid stability and support the increased penetration of renewables into the market.

- The logistics improvement and carbon reduction opportunities from a Port Augusta hub location are extensive and require further definition. For example, this project could remove 500,000 tonnes of heavy road freight from the Adelaide to Port Augusta route, with consequential emissions reductions, road safety benefits and road maintenance savings.

- Will assist to secure existing jobs across the most important existing mining and major metals processing operations in SA.

- Opportunity to engage extensively with indigenous and other community groups for employment and business opportunities.

- Opportunity to reduce CO2 emissions from local infrastructure projects including the South Road Tunnels project, which is projected to consume 780,000m3 of concrete @ average 320kg cement per m3. This equates to 250,000 tonnes of cement which if replaced by 50% SA Produced SCM results in a reduction of 110,000 tonnes of CO2 throughout the entire project versus normal portland cement.

- Strong alignment and delivery against state, national and international climate change policy objectives.

NEXT STEPS

Hallett Group was delighted to recently be awarded a federal government grant of $20 million under the modern manufacturing initiative. This grant together with the support of its existing finance partners has given Hallett the confidence to proceed with its full green cement transformation project. Key future actions are:

- Complete full detailed design works for Port Augusta Processing hub, achieve project approvals and place orders October 2022 Complete construction and commission Port Adelaide Distribution hub May 2023

- Complete construction and commission Port Augusta Processing plant June 2024

Hallett is looking to scale up its workforce in Adelaide and will also establish a major workforce and supplier/contractor network in the upper Spencer Gulf region. Should you wish to register your interest in working for the Hallett group, assisting us in the project, becoming a customer or if you just have some questions you would like answered please direct them to greencement@hallett.com.au and Hallett will be in touch.

The Hallett Team together with the Mayors of Port Pirie and Port Augusta, supply partners and members of parliament came together recently to promote the Green Cement Transformation Project.

Through this project Australia can become an international leader in the beneficiation and usage of SCMs in green cement. This will deliver significant and quantifiable sustainability, employment, and financial benefits to a broad range of South Australian and Australian stakeholders and businesses.

Kind regards

Kane Salisbury

Hallett Group – CEO

E. ksa@hallett.com.au

Mark Pickard

Hallett Group – Managing Director

E. msp@hallett.com.au

WHAT PEOPLE ARE SAYING ABOUT HALLETT’S GREEN CEMENT TRANSFORMATION PROJECT

Hon. Tom Koutsantonis Member for-West Torrens and Minister for Infrastructure and Transport, Energy and

Mining Said

“The Green Cement Transformation Project demonstrates South Australia’s attractiveness to investors wanting to pursue low emissions technologies. Building homes and cities using low emissions materials and leveraging renewable energy is the kind of innovative investment the Malinauskas Labor government plans to attract by maintaining South Australia’s reputation for global leadership in renewables.”

John Whelan: CEO Department of Infrastructure and Transport Said

“The Department for Infrastructure and Transport is committed to delivering low emission and operations. We have been working with our delivery partners to drive increased use of low carbon concrete. It is exciting to see local suppliers respond to the climate challenge and bring low carbon products into market.”

Hon. Rowan Ramsey Federal Member for Grey Said

“This project met the objectives of the Coalition Government in reducing emissions through technology not taxes. The Modern Manufacturing Initiative is designed to deliver new industry in a changing world and will help us meet out international reduction targets. I am hopeful the new Government will continue on this pathway and wish Hallett group every success. It is an exciting project.”

Hon. Geoffrey Brock State Member for Stuart said

“I congratulate the Hallett Group for this innovative idea of using existing waste product from Nyrstar, Port Pirie, and the old Power Station at Port Augusta. I look forward to working collaboratively with the group to endeavour to get this project to fruition. Looking forward to the financial closure and construction of the operation that will add a great economic benefit to the people of the Upper Spencer Gulf”

Hon. Eddie Hughes State Member for Giles Said

“This will be a great project for the Upper Spencer Gulf with benefits for Port Augusta and Port Pirie. We need to diversify our economies and provide jobs plus using what is now a waste product and turning it into an input to green cement production. This will be a real demonstration of industrial ecology and it will add to the overall thrust to reduce greenhouse gas emissions. “

Mark Pickard: Owner of Hallett Said

“In my 40 years in business I have never been more excited about our future and our ability to benefit the community”

Kane Salisbury: CEO of Hallett Said

“I am incredibly proud of the team for pulling this truly disruptive innovation project together despite all the challenges. I am delighted to be able to work closely with our supply partners in Port Augusta Operations and Nyrstar to create a win win solution for all of us and the communities we operate in. I am really looking forward to growing our team to deliver this amazing project”

John Fullerton, Director – Port Augusta Operations

“We are very pleased to be partnering with the Hallett Group as we work together to transform this former coal power station site into a modern and green manufacturing, logistics and export hub, bringing back jobs, growth and opportunities to regional South Australia.”

Dale Webb, Nyrstar Vice President Australian Operations Said

“We are excited to be partnering with the Hallett Group on this important Green Cement Transformation project that will reduce emissions, create jobs and maximise the value of Australia’s minerals.

“It is another important way Nyrstar Australia is working with our key partners like the Hallett Group to innovate, prepare for the future and deliver environmental outcomes for our communities and the world.”

Hon. Mayor of Port Augusta Brett Benbow and CEO John Banks Said

“We welcome the economic development opportunity afforded by the project and very much look forward to working with all parties and the Port Augusta community as it progresses.”

Hon. Mayor of Port Pirie Leon Stephens Said

“Port Pirie Regional Council has great interest in this particular project and particularly with the involvement of the other two cities in the Spencer Gulf by-product of any manufacturing process should always be managed wisely and this project exactly encapsulates that , with the outcome being green cement to go towards new projects , is very exciting is going we look forward to the future with many buildings using green cement and the clean-up of our by-product from our manufacturing sites all the best for the future”

Greg Clothier: Chairman Global Maintenance USG

‘Global Maintenance USG (GMUSG) are excited with the recent announcement from Hallett on the Green Cement Transformation Project. Local procurement plays a significant role in ensuring the flow-on effects from regional operations are beneficial to local communities. This creates a practical ‘shared value’ approach to project activities within regional South Australia. The Board and Management would like to thank Hallett for their commitment to the Upper Spencer Gulf Region. We look forward to continuing to work with the team at Hallett to ensure local content is a significant pillar of the project.’

Mike Vacy-Lyle: Group Executive Business Banking, Commonwealth Bank of Australia Said

“Commonwealth Bank supports the transition to net zero and is helping our clients to pursue the opportunities it presents. We are pleased to be supporting Hallett Group as they embark on this innovative project, and the transformative impact it will have on reducing emissions caused by cement and concrete while generating jobs at the same time.